9 Fool proof Food Allergen Management tips

Two bakers making bread products in a bakery

As EHOs and food safety consultants we regularly come across food businesses who have inadequate or incorrect food allergen information, and don’t have procedures in place to prevent cross contact of allergens This can cause serious problems including putting customers at risk, poor FHRS ratings, fines and worse.

The most common reason food business owners give for not priotitising their food allergen controls is that they haven’t got enough time to do it and this is the most worrying part, because:

“Putting in place food allergen management procedures is not something you do when you have a bit of spare time! It’s a fail safe system that has to be in place every time you open the door to customers and getting it wrong is not an option.”

What is meant by cross contact of allergens?

This is when an food containing allergens is transferred to another food, for example when crumbs of white bread (made from wheat flour) are transferred to gluten free bread if the same toaster is used- this can often be enough to create an allergic reaction!

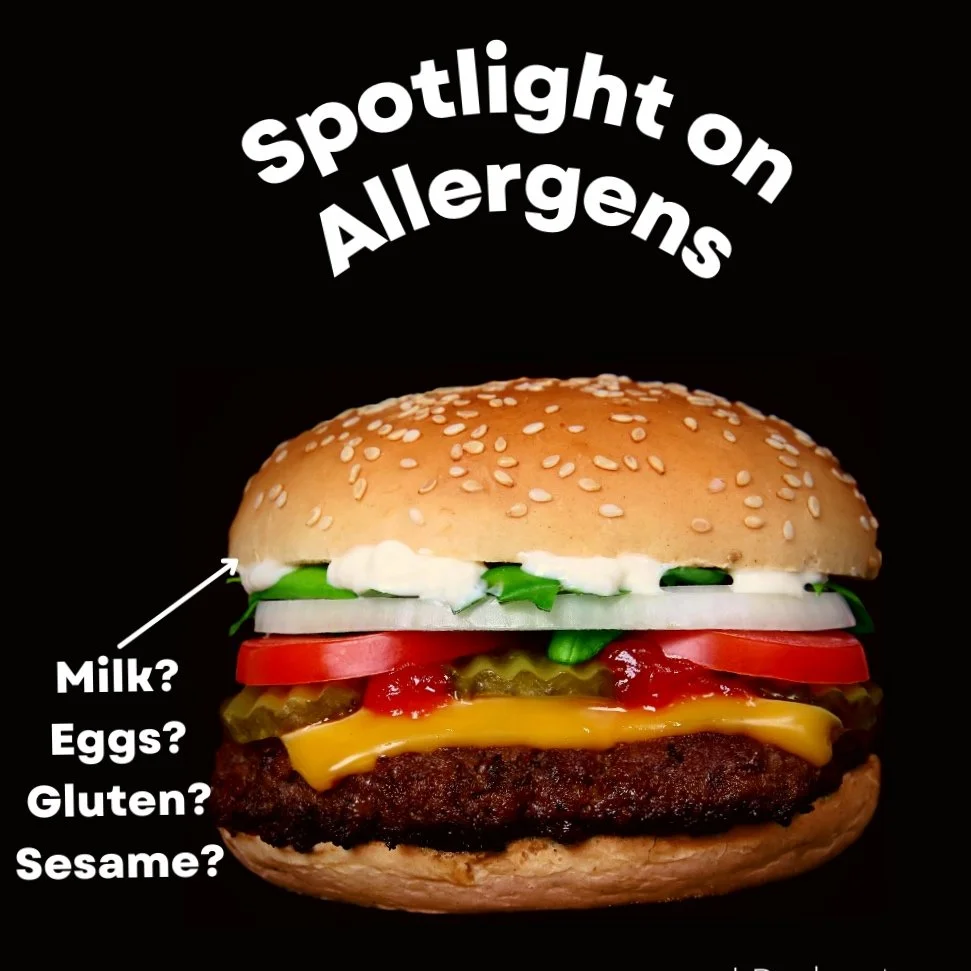

A burger showing the allergens it could contain

9 top tips to Shine the Spotlight on Allergens

Inform customers of your food allergen information by displaying a sign on the wall, counter or menu as this is a legal requirement. Make sure it is in an obvious place and is easy to read.

Use approved suppliers and check food labels on delivery. Reject substitutions and changes to products ordered if the allergen information is not provided.

Write down the 14 food allergens in ALL menu items and keep it up to date. Go through each menu item and record the allergens on an allergen matrix ( download the chart for free from https://www.food.gov.uk/sites/default/files/media/document/allergen-chart.docx)

Include ‘May Contain’ allergens identified on ingredients lists from manufacturers from genuine cross contact during their production. Label them on the matrix as ‘MC’. It can depend on an individual customers sensitivity and how severe their allergy is to whether they will be able to eat food which has a ‘may contain’ allergen in it.

When displaying loose food such as cakes, pastries, sandwiches etc. put signs displaying the allergens in each product next to the item. Separate them in the display to avoid cross contact happening.

Write down the controls you have in place to prevent cross contact of allergens in storage, preparation and service in your food safety management system or HACCP plan. If using SFBB complete the food hypersensitivities section. Keep documentation up to date.

Make sure staff know how to prepare and serve a meal for a customer with a food allergy safely to prevent cross contact of allergens. This could include washing hands, wearing disposable gloves and aprons, using clean and separate equipment etc. Use signage in the kitchen as a reminder.

Store food allergens safely in labelled, lidded containers to avoid cross contamination.

Make sure you have procedures in place if someone asks about allergens. Staff should start the conversation about food allergies as soon as possible. Talking with a customer about their allergy or intolerance will help to give them accurate information so the customer can make an informed choice on what to eat safely. Nominate a staff member as an ‘Allergy Champion’ on each shift in the kitchen and front of house. They should handle all food allergy queries from both customers and staff to keep communication simple.

Document any allergen incidents and ‘near misses’ to identify recurring problems and trends. Learning from any mistakes may help stop a more serious incident happening in the future.

Happy staff talking in a kitchen

Train your staff on food allergens

Make sure ALL YOUR STAFF (kitchen and front of house) receive FOOD ALLERGEN AWARENESS TRAINING that is relevant to your business.

Training can be completed online or in a classroom setting and refreshers must be completed regularly to keep their knowledge up to date.

Chefs cooking in a busy kitchen

Food Allergen Kitchen Audits

Check procedures are working by carrying out a regular allergen audit that will help identify any issues or non-compliances.

Allergen audits can be done in-house or by a 3rd party auditor and should be carried out at different times on different days.

The allergen audit could include a mystery diner to check that the allergen policy is being followed from when the customer walks through the door to when the food is served.

Contact Us

If you would like more information on managing food allergens, allergen audits or allergen awareness training get in touch.